Introduction of the laboratory

Prototyping is a process that gives an objective visualization to the 3D design, which until now was only visible in the software environment, as a result, it provides the possibility to identify any problems or mistakes in the product design in its early stages. . By troubleshooting in the early stages of product development, the possibility of errors in the final phase of product development is reduced and the time and costs of project implementation are saved. In the bronze industrial group, prototyping using various methods such as:

Hand lay up

• 3D printing using the FDM method

• Casting using silicone and epoxy resin

will be done. The use of the types of methods listed above depends on the geometry of the sample, its dimensions and the quality of its surfaces. Some temporary molds made with silicone or epoxy resins can be used up to 1000 times in an injection molding machine, but if using 3D printing method or manual porcelain layer every time.

Exam services

In the field of testing services, Burns Laboratory provides laboratory activities for conducting tests in the field of its scope of application. These services are provided for internal and external customers, and the laboratory system has been developed in such a way that no problem prevents Fimabin’s cooperation and effective service to customers.

The tests that can be performed in the bronze laboratory are divided into the following seven general categories:

Air Manifold Explosive Strength Evaluation Test (TN030-14050)

In the field of testing services, Burns Laboratory provides laboratory activities for conducting tests in the field of its scope of application. These services are provided for internal and external customers, and the laboratory system has been developed in such a way that no problem prevents Fimabin’s cooperation and effective service to customers.

Dashboard strength evaluation test against airbag explosion

By relying on advanced and up-to-date equipment in the field of high-speed imaging, the Burns Industrial Group laboratory can test and record the airbag performance under static conditions and with high quality (800K/4000 fps). The images recorded under these conditions provide the possibility of a detailed examination of the behavior of the dashboard assembly (passenger airbag) and the steering wheel assembly (driver’s airbag) during the opening of the airbag, because the tension and impulse resulting from the opening of the airbag, the dashboard assembly or the steering wheel affects and even in some cases it leads to the throwing of particles caused by breakage and even dangerous fractures, which pose a threat to the life of the passenger or the driver.

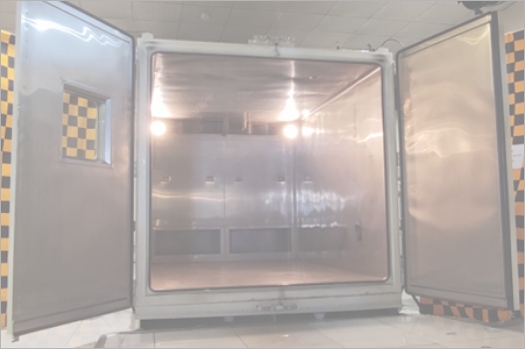

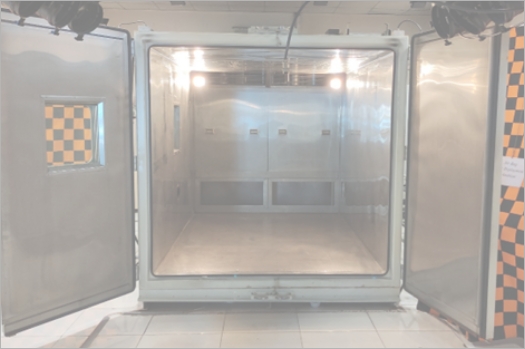

By using the environmental chambers at its disposal, the Burns Industrial Group laboratory is able to test the front assembly of the car dashboard according to working standards at minus 35, plus 85 and 23 degrees Celsius in new condition and after environmental and solar aging and even in installed condition. Prepare and report the mentioned test on the half body of the car using the airbag test equipment of HuDe, Germany, in accordance with the latest technologies in the world in the field of this test. This company is one of the most well-known manufacturers of ultra-safe laboratory equipment in the world, which has exported its products to all parts of the world and has many international approvals.

The cameras that the Burns company laboratory uses for high-speed filming of this test are made by one of the most reliable and famous companies in the world in Japan, called PHOTORON, which has provided countless facilities for various automotive and non-automotive research and studies.

HDT thermal deformation temperature

This device is used to measure the deformation temperature of plastics under load, which is designed based on ASTM D648 and ISO75 standards. With this device, it is possible to predict the behavior of plastics when they are subjected to final application conditions such as increasing temperature and applying physical load, and to define measures to strengthen or stabilize it.

This device has an oil bath whose temperature increases uniformly and at a certain speed during the test, and this causes a standard plastic sample to be prepared, which is subjected to a specific physical load (weight) according to its thickness and width. be deformed In this experiment, we seek to determine the temperature at which this plastic sample reaches its thermal deformation limit. This deformation limit is determined by the test standard, which also depends on the dimensions of the test sample.

For example, imagine your car parked in the alley on a hot summer afternoon and you have placed a book package on its back window. When you go to your package again, we hope that the first thing that catches your attention is not the recess of the window and its deformation.

We perform the HDT test with this device to prevent such defects.

Communication with the laboratory

To complete the laboratory service form, read the laboratory fees and charges form, then submit it to Bronze Laboratory with the seal of the applicant company. Also, for advice and the possibility of doing tests with the address

Email: brc1362@gmail.com

Or call 021-44987563 extension 502.